Matala FILTRATION MEDIA Are you looking for an all-round solution for mechanical and biological filtration? Matala represents the latest generation of filter media that are rapidly gaining interest in the market. Thanks to the multiple advantages Matala is the ultimate answer for your needs. Matala is made of curly fiber Thermo-Polypropylene Compounds (TPPC) or Thermo-polyethylene Compounds (TPEC) that are formed into layers and shapes of different thickness. The formula of the TPPC and the thickness of the fiber used will determine the structure of the filter media, their specific surface, their density and stiffness.

|

|

|

|

| FSM190 extra low density. | FSM290 medium density. | FSM365 high density. | FSM460 extra high density. |

Matala filter media Applications: Individual household wastewater treatment, Septic tank effluent wastewater treatment, Domestic sewage treatment, Suburban/farm village water, Draining/infiltration, River purification, Storm water treatment, Industrial wastewater treatment, Livestock farm wastewater treatment, Marine habitat rehabilitation, Grey water treatment, Wetland, Gas and fluid contact media, Air scrubbing.

| Matala filter media Specifications | ||||

|

MatalaType Product Code |

Color | Specific surface | Fiber diameter | Free volume % |

| ft2/ft3 , m2/m3 | inches , mm | |||

| SM150 | Black | 46±3(ft2/ft3) , 150±10 | 0.0748 , 1.9±0.1 | 93 |

| SM190 / FSM190 | Black | 58±3(ft2/ft3) , 190±10 | 0.0669 , 1.7±0.1 | 92 |

| SM290 / FSM290 | Green | 88±3(ft2/ft3) , 290±10 | 0.0354 , 0.9±0.1 | 93 |

| SM365 / FSM365 | Blue | 111±3(ft2/ft3) , 365±10 | 0.0217 , 0.55±0.1 | 94 |

| FSM460 | Gray | 140±3(ft2/ft3) , 460±10 | 0.0197 , 0.5±0.1 | 94 |

• The above specifications are subject to change without prior notice

Matala in Sheets |

*The above specifications are subject to change without prior notice |

|||||||||||||||||||||||||||||||

Matala in Rolls |

• The above specifications are subject to change without prior notice. |

|||||||||||||||

Matala in Tube |

• The above specifications are subject to change without prior notice. |

|||||||||||||||

High filtration efficiency, allows for smaller / less filter tanks.

- Gentle Mixing: random fibers create micro turbulence and a 3-D flow.

- Longer Contact: a turbulent flow results in longer and intensive contact.

- Interstitial spaces enhance build-up of the biofilm.

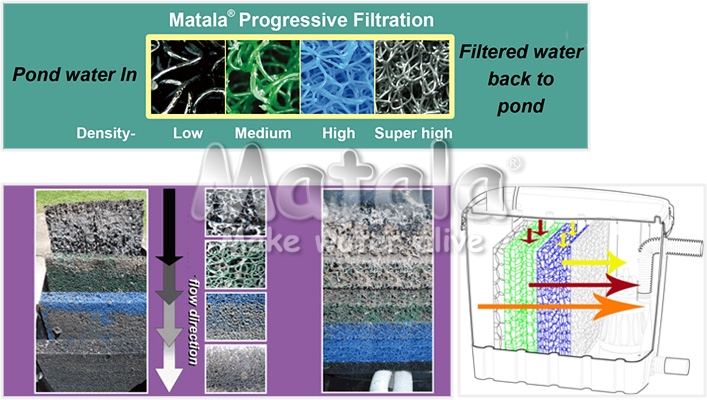

Choice of types and densities of Matala are function of your influent water characteristics and target effluent quality. Progressive depth filtration increases the sludge holding capacity and anticipates clogging.

Matala Progressive in Mechanical Filtration :

The pictures attest to the high filtration efficiency achieved with the progressive density Matala filter pads. The filter can hold a huge volume of sludge (10 times of its own weight) without clogging.

Matala® Progressive in Biological Filtration:

Higher Filtration efficiency allow for smaller / fewer filter tanks.

- Gentle mixing: random fibers create micro turbulence and a 3-D flow.

- Longer contact: a turbulent flow results in longer and more intensive contact.

- Interstitial spaces enhance build-up of the biofilm.

2.Longer retention of air bubbles in between the web structure fibers.

|

|

|

|

Available in different shapes (Sheets, Rolls, and Tubes) to fit your existing tanks or space.

Application of Matala® in aerobic wastewater treatment

Adding Matala® in a proper volume ratio to the aerobic chamber will help:

- to stabilize biofilm.

- to reduce the final amount of sludge.

- to build the systems tolerance when influent characteristics and flow rates changes.

- to reach stable effluent quality.

|

Aerobic Chamber

|

|

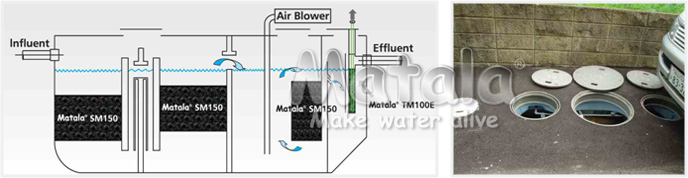

On-Site small aerated wastewater treatment system.

System installed as standard process with CE certificated by European company. |

Aerobic Chamber

Application of Matala® in combined anaerobic and aerobic household wastewater treatment system.

On-Site installation for individual household wastewater treatment system

- V(media)/V(tank) ratio: 40%(for Anaerobic tanks). 30%(for Aerobic tanks).

- Influent: BOD 200mg/l.

- Effluent: BOD < 20mg/l, COD < 30mg/l, SS:4mg/l. (System installed as popular standard process in Japan).

Application of Matala® in 2nd treatment and 3rd tratment process.

|

On-Site wastewater treatment installation for Swine farm (10,000 head of swine)

|

Application of Matala® in sedimentation process.

|

3-Dimensional fiber distribution, easier to capture the SS in the water.

|

Pictures above shows 0.1m3 of SM-290 can capture the sludge 24.3 kg.

Application of Matala® in storm water treatment.

|

Matala® Can be applied in

|

Application of Matala® in wetland.

|

|

Application of Matala® in iron removal.

|

On-Site installation (Underground water Iron Removal)

|

Applications for evaporative cooling wall

|

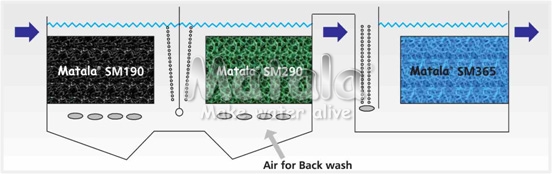

How to clean Matala biofilter Chamber:

| Back Wash with Air : | Matala Biofilter Back wash |

|

|

Design Examples :

1. River Purification :Matala filter media installation QTY and Type Installation Design Example.

Download:How to calculate Matala filter media QTY and type.pdf ![]()

2. Wastewater Treatment plant for elementary school : pdf files : long hwa school.

Download:Matala Biofiltration in Long hwa elementry school wastewater treatment plant design worksheet

|

|

|

SHEET:

For square or rectangular tank/filter.

|

|

Dimensions

| Model Specifications |

SM190 | FSM190 | SM290 | FSM290 | SM365 | FSM365 | FSM460 | |

| Color | Black | Green | Blue | Gray | ||||

| Specific surface (ft2/ft3) / (m2/m3) |

58±3 / 190±10 | 88±3 / 290±10 | 111±3 / 365±10 | 140±3 / 460±10 | ||||

| Fiber diameter (in) / (mm) | 0.067 / 1.7±0.1 | 0.035 / 0.9±0.1 | 0.022 / 0.55±0.1 | 0.02 / 0.5±0.05 | ||||

| Free volume (%) | 92 | 93 | 94 | 94 | ||||

| Weight per full sheet (lbs) (kg) |

6 2.8 |

8 3.8 |

6.4 2.9 |

7 3 |

5.5 2.6 |

6 2.8 |

7.5 3.4 |

7 3 |

| Weight per half sheet (lbs) (kg) |

3 1.4 |

4 1.9 |

3.3 1.5 |

3 1.5 |

2.8 1.3 |

3 1.4 |

3.7 1.7 |

3 1.5 |

| Weight per box (lbs) (kg) |

35 16 |

46 21 |

37 17 |

37 17 |

33 15 |

35 16 |

42 19 |

37 17 |

| Dimensions : L x W x H (in) (cm) |

SM Series: 48x39.5x1.6 (F) ; 39.5x24x1.6 (H) FSM Series: 48x39.5x1.5 (F) ; 39.5x24x1.5 (H) |

|||||||

| Dimensions per box : L x W x H (in) (cm) |

49x40x8 (FB) ; 40x16x25 (HB) 122x102x20 (FB) ; 102x40x62 (HB) |

|||||||

- Product code of "FSM" stands for Flex-Matala®.

- (F): full sheet (H): half sheet (FB): full sheet 5 pcs/box (HB): half sheet 10pcs/box.

- The above specifications are subject to change without prior notice.

Custom Pack sheets

|

|

|||||||||

Roll: Great for Vortex, Round filter or Barrels.

|

|

|||||||||||||||

Pre-Cut

|

|

||||||||||||||||||||

Advantages

1. Easy to Clean:

Use a submersible water pump with a hose of sufficient diameter and pour a good volume of pond water over the Matala® media.

OR

Pour a full bucket of pond water over specific sections of the Matala® filter media.

OR

Temporarily remove 2 sheets of Matala® and shake the remaining sheets up and down in the filter tank; drain the chamber.

OR

Remove the Matala® media from the tank; dirty water falls off; drain chamber.

Important Notes:

Remove Matala® media only if strictly necessary; The above picture proves Matala® releases its dirt quite easily.

It is okay to gently tap the media on the ground to dislodge the dirt.

Overzealous cleaning is not necessary and will lose too much bacteria. Keep it gentle.

Shake the media up and down in the filter tank; drain chamber.

Something to know before you start cleaning your Bio-filters:

Bio-filters are full of live micro-organisms. Filter media are the bearers of this life. Over-zealous cleansing or purifying the filter media will unbalance the filter ecosystem by eliminating or killing this essential life. Disinfecting or drying of washed media only makes sense in cases where the whole pond needs to be disinfected or dried out.

In essence, cleaning a bio-filter should be only done with the intention to:

Eliminate excessive organic waste (fish excrements, excessive food, plant remains) from the first section of the filter (sedimentation chamber, vortex, etc...). Such need to be done more often to avoid putting an extra burden on the real bio-filter.

Rinse out excessive detritus or accumulated bacterial flock from the latter section of the filter to avoid plugging of the filter media, which would create adverse anaerobic conditions.

Improve the living conditions of the nitrifying bacteria and micro-organisms that thrive in the bio-filter.

Please note that when using Matala® media in a well-designed bio-filter with proper flow rate it will be difficult to see plugging of this media. Excessive detritus or bacterial flock will tend to slug of and settle to the filter bottom. Purging the filter will take away this detritus.

To clean the real bio-filter section: "Use volume – no pressure"

2. Easy to Cut and Fit:

Matala®filter pads ared rigid and yet still slightly pliable.

It will hold it’s open 3 dimensional internal structure even if purposely crushed.

It is easy to cut. Use a hole saw to cut circles for pipework. Use a jig saw with a fine tooth blade, or 8" long sharp carving knife for free-form shapes. You can also use band saw, with a very fine tooth blade, or turn the blade and use the backside as knife.

Use a masonry blade turned backwards on a circular saw.

3. Four densities allow for steps-wise transition from mechanical to biological filtration:

4.High free volume for smooth, even water flow throughout

5.Light weight.

6.Versatile and durable

7.Made of Thermo-PE or PP compounds; nontoxic to environment.

8.Form-stable

9.Self-supporing

Sample Designs

Submersed Bed Filters (Matala Progressive Filtraion) |

Vortex |

Sedimentation Chambers |

Trickling Filters |

Protection of Fish Fry/ Spawning Mat |

Anti-Clogging of Pumps |

Oxygenation or De-gassing of underground water |

Spawning Mat |

Protection of Plant Basins in Ponds |

Surface Skimmers |

Mechanical Pre-Filtration |

Products

Products